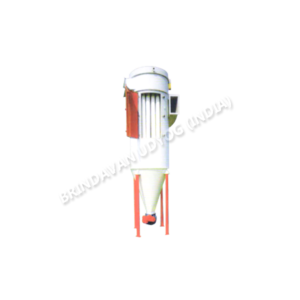

HAMMER MILL

Hammer mill is the most broadly used grinding mill and among the oldest. Hammer mills consist of a series of hammers hinged on a central shaft and enclosed within a rigid metal case. It produces a size reduction by impact. The materials to be milled are struck by these rectangular pieces of hardened steel which rotates at high speed inside the chamber.

Product Description

Features of Hammer Mill:

- Large opening for flexibility

- Fully lined crushing chamber for longevity

- Liners are bolted for easy change out

- Grate bars and screens for accurate product sizing that are easily replaceable

- Hammers or rings allowing flexibility

- Forged alloy steel and extreme duty shaft allowing reduced vibration and longer bearing life

- Positive lock housing for extra security from blowouts and dusting

- Adjustable grinding plate for process control

- Multiple rotor configurations to suit any material

- Large discharge opening

Hammer mill Industry & Application Usage

- Agricultural Industry

- Energy Industry

- Aggregate Industry

- Industrial Applications

| Machine details | A in mm |

B in mm |

C in mm |

D in mm |

E in mm |

| Hammer mill 18″ | 1244 | 1355 | 445 | 555 | 1125 |

| Hammer mill 24″ | 1465 | 1445 | 700 | 610 | 1280 |

| Hammer mill 30″ | 1770 | 1765 | 700 | 670 | 1380 |