Product Description

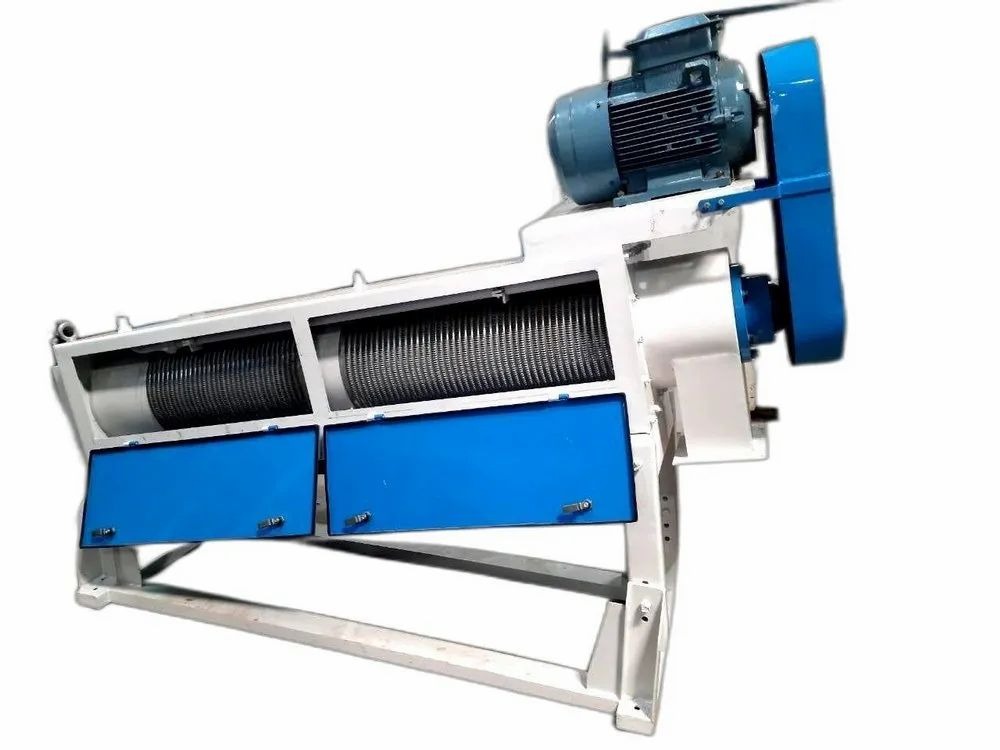

Wheat Intensive Dampener

The intensive dampener is an essential tool for achieving optimal moisture levels in grains, particularly wheat. It allows for water addition rates of up to 4%, ensuring minimal abrasion and breakage during the process.

How It Works

Designed as an inclined edge conveyor, the dampener operates efficiently to mix water with the grain. Here’s how it functions:

- Grain Input: Grains enter the dampener through the front inlet.

- Water Dispersion: Water is added near the inlet, mixing thoroughly with the grain.

- Mixing Process: The mixing rotor blades move the grain and water mixture upwards. This intensive mixing ensures even water distribution.

- Output: Fully moistened grains are discharged from the machine outlet.

Salient Features

- Effective Mixing: The inclined design thoroughly mixes water with the grain, preparing it perfectly for further dampening in grain bins.

- Automatic Water Control: The water control valve at the inlet automatically shuts off water flow when no grains are present.

- Energy Efficient: Low energy consumption ensures cost-effective operation.

- Hygienic: Excellent sanitation is maintained throughout the process.

- Easy Maintenance: The top cover can be easily removed for maintenance purposes.

- Durable Construction: All parts in contact with the product are made of stainless steel for longevity and hygiene.

Upgrade your grain processing with our advanced wheat-intensive dampener, which delivers consistent and high-quality results.