MILL SPOUT CLEANER MACHINE

Major features of the Mill Spout Cleaning System are:

- Low cost

- Very robust and portable

- Simple to use

- One-man operation

- Variable speed control

- Cleans pipe lengths from 6-60m and diameters from 4-400mm

- Adapts to clean chillers, condensers, boilers, drains, ductwork

- Variety of tool heads to suit a variety of deposits, dimensions, and blockages.

Product Description

Preventative Maintenance = increased efficiency

– Increased productivity

– Improved throughput

– High-quality product

– Reduction in downtime

– Reduce costly replacements

– Reduce the need to repair

– Prevent damaged spouts

– In-house capabilities

The Costs of Build-ups & Blockages

• Low product flow

• Ineffective fumigation

• Possible Infestation

• Damaged pipework

• Expensive replacement

Traditional treatment methods

• Chemicals

• Pull through brushes

• Rubber hammer

BUI – the solution

• Robust and lightweight

• One-man operation

• Clean 8-12 meter spouts in 30 seconds

• An 8-sifter mill in one day

• Pipework free from damage

Design

Compact and robust – first to be designed & manufactured by a contractor.

Power

110v and 240v options, High-efficiency motor, Cleaning range 25mm to 500mm, (1” – 20”) diameter.

Variable Speed

High torque throughout the speed range of 0-1500rpm provides control and versatility for different applications.

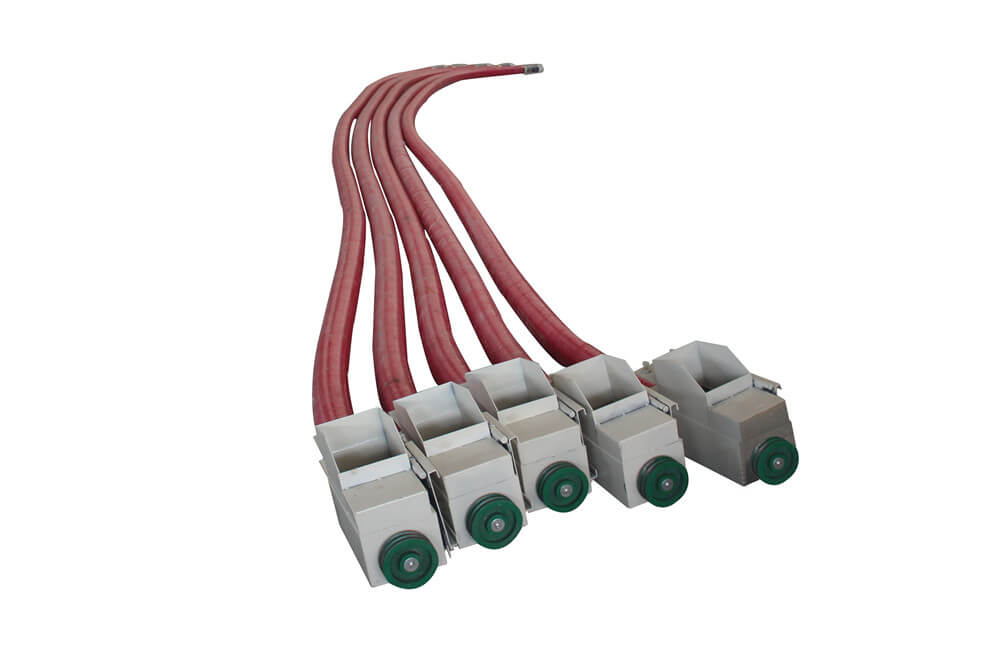

Steel Spout Flexible Drive

Food Grade Coating, Crush Resistant,8 & 12-metre lengths, Greater reliability

Includes

Wide range of brushes and attachments.

For use in:

• Flour Mills

• Rice Mills

• Maize Mills