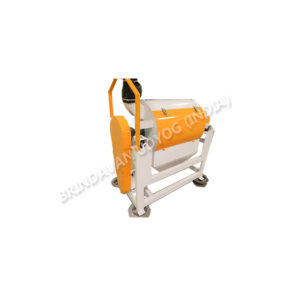

Product Description

The product enters through the eye of the machine and then passes through rows of pins rotating at high speed between stationary pins. The product particles are shattered into fragments as they progress towards the outlet. This action makes a fan effect and a high volume of air is drawn through with the product, keeping it cool. The machine’s grinding action can be controlled by altering the feed rate to the machine and the speed of the rotor.

Features:

- Low energy consumption, high capacity, and operating efficiency.

- Easy and minimum maintenance, hassle-free operation.

- The pin mill cover is hinged which means all of the mechanisms in contact with the grinding material can be easily accessed and cleaned.

- Durability and long lifetime

- The whole pin mill meeting can be vertically mined for maintenance or any needed repair work.

- Noiseless working