SEMOLINA MAGNETIC DESTONER

Semolina is a staple ingredient in many cuisines worldwide, prized for its versatility and nutritional benefits. However, ensuring the purity and quality of semolina can be challenging due to the presence of impurities such as stones, metal fragments, and other contaminants. In this blog post, we’ll explore how Semolina Magnetic Destoners play a crucial role in enhancing semolina quality and ensuring food safety.

Product Description

The Importance of Semolina Quality: Semolina quality directly impacts the taste, texture, and overall appeal of various food products, including pasta, couscous, and baked goods. Impurities in semolina can not only affect the sensory attributes of these products but also pose health risks to consumers. Therefore, it’s essential for semolina manufacturers to implement effective cleaning and purification processes to remove impurities and ensure product safety and quality.

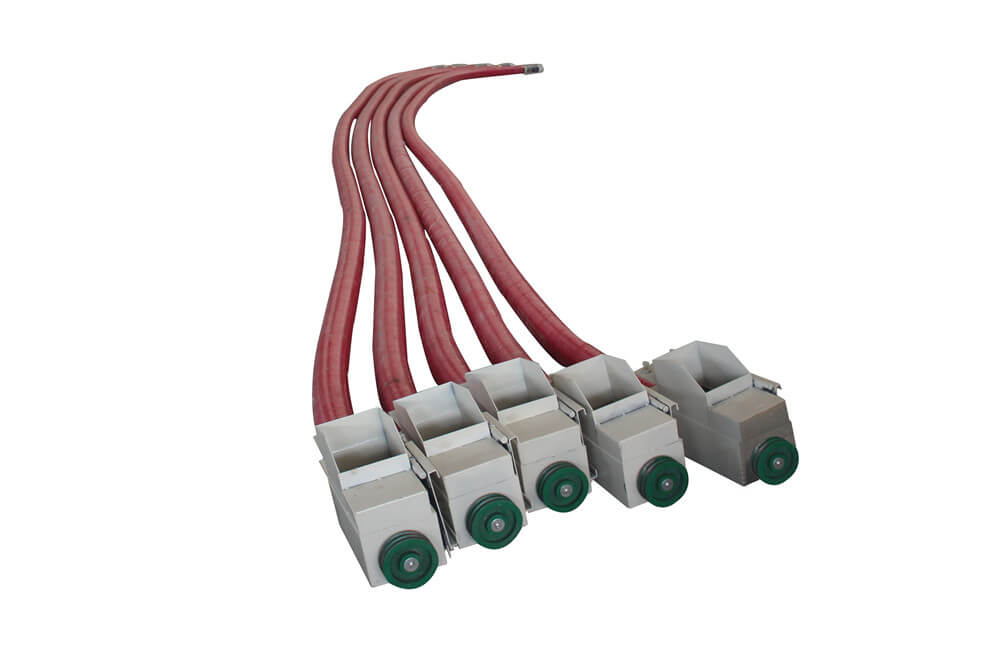

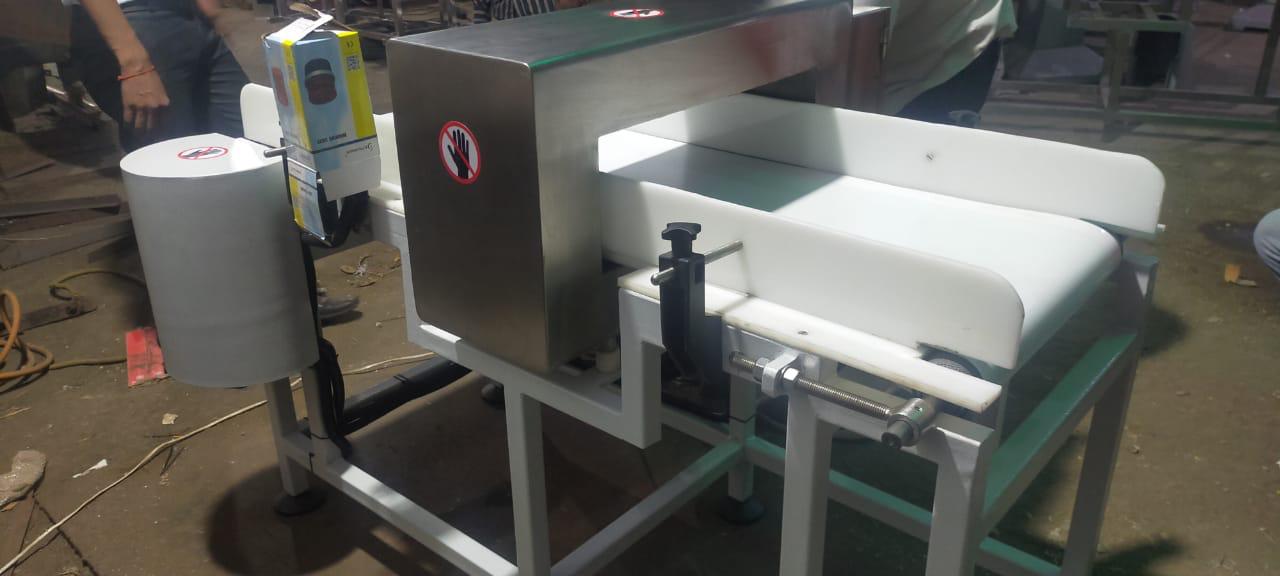

Understanding Semolina Magnetic Destoners: Semolina Magnetic Destoners are specialized equipment designed to remove magnetic and non-magnetic impurities from semolina. These impurities are typically found in raw semolina obtained from wheat milling processes and can include ferrous contaminants like metal fragments, as well as non-ferrous contaminants such as stones, glass, and plastic.

Key Features and Benefits:

- Advanced Magnetic Separation Technology: Semolina Magnetic Destoners utilize powerful magnets to attract and remove ferrous impurities from semolina, ensuring product safety and compliance with food safety standards.

- Dual-Stage Cleaning: With dual-stage cleaning capabilities, these destoners effectively remove both magnetic and non-magnetic impurities, resulting in cleaner and higher-quality semolina.

- High Efficiency and Throughput: Engineered for high efficiency and throughput, Semolina Magnetic Destoners can handle large volumes of semolina with minimal downtime, maximizing productivity and reducing processing costs.

- Easy Operation and Maintenance: Designed for user-friendly operation and maintenance, these destoners feature intuitive controls and simple maintenance procedures, minimizing downtime and ensuring optimal performance.

- Customizable Options: Semolina Magnetic Destoners offer customizable options to meet specific processing needs, including adjustable settings for varying levels of impurity removal and throughput capacity.

Conclusion: In conclusion, Semolina Magnetic Destoners play a critical role in enhancing semolina quality and ensuring food safety in various food processing applications. By effectively removing impurities from semolina, these specialized equipment contribute to cleaner, safer, and higher-quality food products. Semolina manufacturers can benefit greatly from investing in Semolina Magnetic Destoners to maintain product integrity, meet regulatory requirements, and uphold consumer trust in their brands.