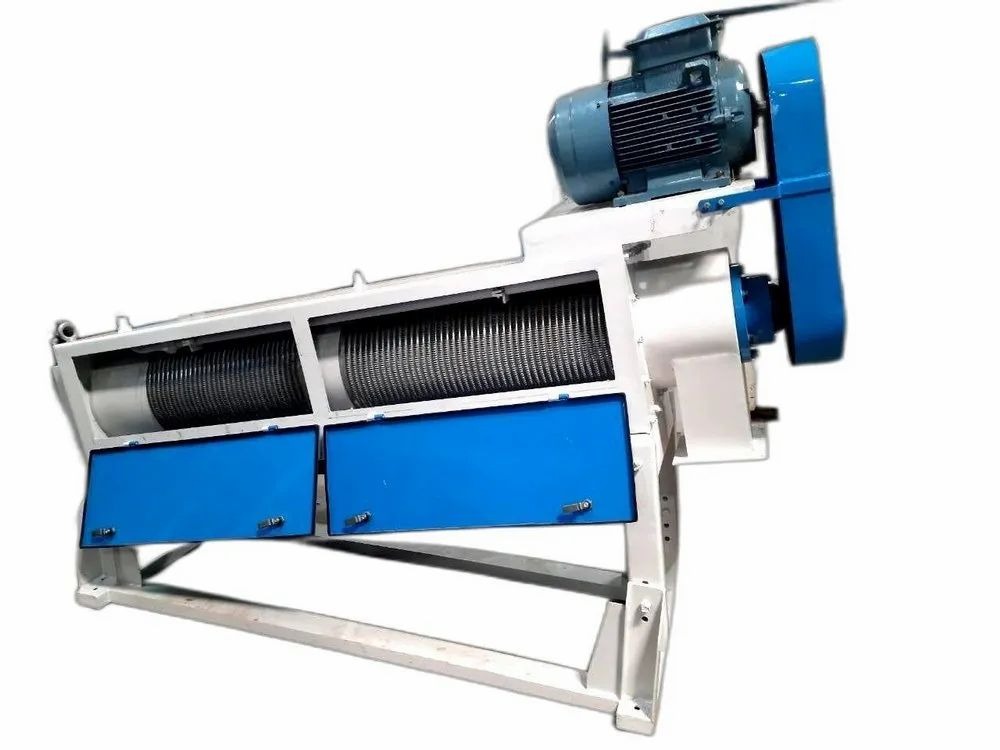

Product Description

WORKING PRINCIPLE OF VIBRO SEPARATOR

The vibrating process is maintained by means of Vibro-motors, which are placed in the center of gravity of the Vibro separator machine. The grain feeding body which is mounted on the rubber shock absorbers by pulsating together and driven by Vibro-motors transports the product into mid-section of the inlet. The grain is separated consistently on the whole exterior of the screen by means of an adjustable regulating gate. If it is necessary, for superior product flow another modifiable regulating gate can be fixed to the inlet of the screen. When the grain passes through from the first screen to the second one, larger size impurities or foreign particles are kept by the first screen and directed to the coarse offal discharge line.

FEATURES & ADVANTAGES OF VIBRO SEPARATOR

- Low energy consumption, high capacity, and operating efficiency.

- Easy and minimum maintenance, the hassle-free procedure by using Vibro-motors.

- Toughness and long lifetime.

- Rapid and easy replacement of mesh and practical cleaning possible.

- Soundless working.

| Machine Details | A – in mm | B – in mm | C – in mm | D – in mm | E – in mm | F – in mm | G – in mm | H – in mm |

| Vibro Separator 1000 | 215 | 400 | 1850 | 2635 | 604 | 1825 | 1725 | 1445 |

| Vibro Separator 1200 |

215 | 400 | 1850 | 2635 | 604 | 1825 | 1725 | 1645 |